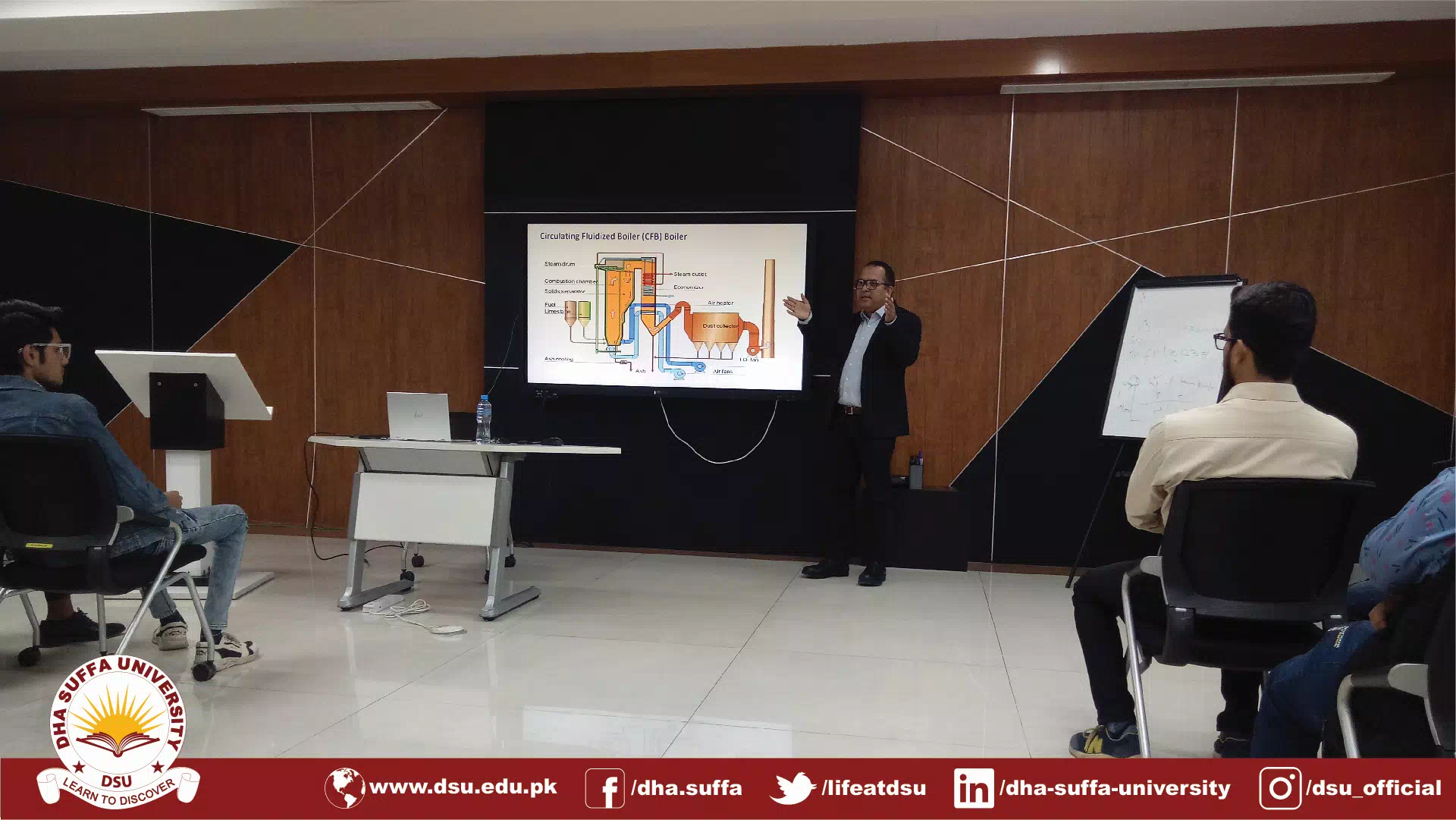

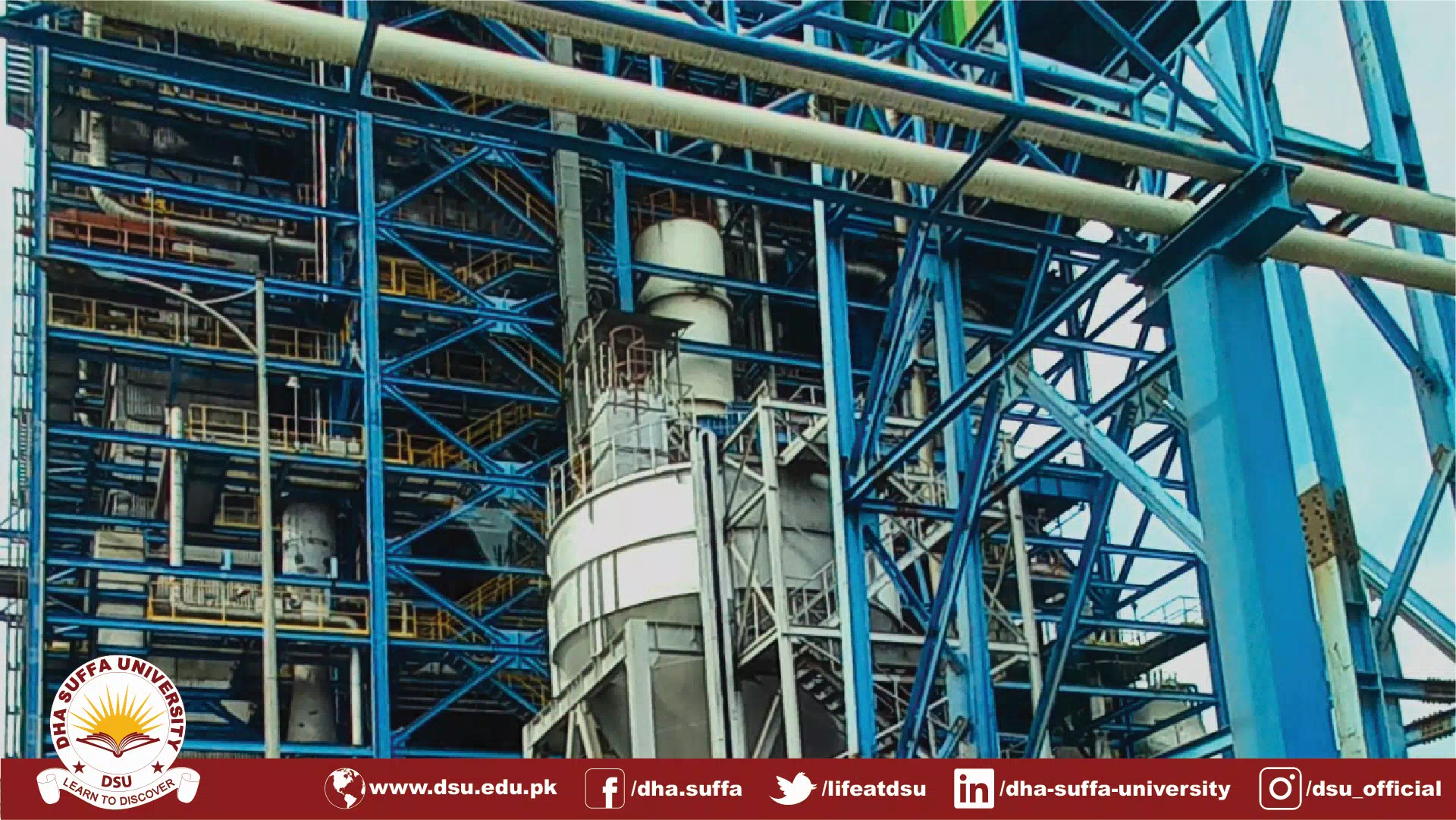

DHA Suffa University’s Mechanical Engineering Semester VII students embarked on a remarkable visit to FFBL Power Company Limited on December 19, 2023. Organized by Engr. Naveed Ahmed Khatri, and accompanied by Engr. Muhammad Wasil and Engr. Naveed, the day featured presentations on FFBL and FPCL, covering company policies, safety guidelines, plant operations and the role of mechanical engineers at FPCL. A lively Q&A session was followed by an exclusive site tour, offering students practical insights into the industry. The day concluded with a networking tea session, enhancing connections with industry professionals. This visit served as a pivotal bridge between theory and practice, enriching the students’ educational journey. DSU is thankful to the host Mr. Basit Iqbal Khan for leading this visit which proved to be an enlightening experience for all.